On August 23 Puffin changed her tack in the paint shop as if under sail. The travel lift crew and I flipped the boat on her port side like a well-oiled machine. And the car tires had evidently done their job, since no compressed spots were found on the hull. What a relief! The other good news was that Janos came back from Florida to help me further, so our trio with Glenn continued working as a seasoned team.

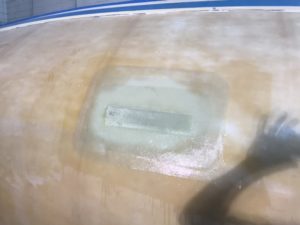

We found several suspicious white spots on the starboard side while we were preparing for the lamination, but one of them about amidships was an especially big one, about 2.5‘ x 1‘. I started to sand it off as Glenn had suggested, and I penetrated the foam of the stringer (inside of the hull) without seeing any fiberglass. It was not a pleasant finding, but pretty convincing validation of my call to pursue this extra lamination on the hull.

First stage of the repair: I filled the opening with chopped glass mixed with Seahawk resin. This mixture, like putty but much stronger due to the chopped glass, filled up all the cavities and created a good foundation for the patching and further lamination.

We completed the starboard lamination within only two days, thanks to the routine we had mastered while working on the port side. And my estimate on the ordered material (fiberglass and resin) was almost perfect. We fell short on resin, due to the fourth layer we had to add on the starboard side, where my initial sloppy gelcoat peeling had carved too much fiberglass from the hull. But Mark Andres saved the day, rushing to our shop with some leftover Seahawk resin from his basement.

The endeavor proceeded with the mirror repetition of our previous actions on the port side: Alexseal high buildup primers, Alexseal filler, longboarding, and coats of primers, again… there is no end until complete exhaustion! But our spirits are high, Glenn and Janos are good sports, and Mark Andres (Seahawk) and Alastair Smith (Alexseal) are the best team players. Their advice and timely deliveries have kept us on track.

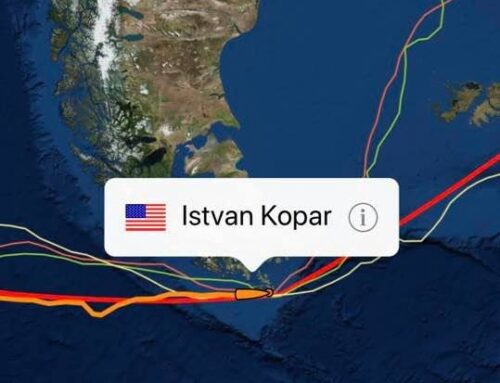

Nevertheless, speed bumps are inevitable, especially in boatbuilding. I am feeling huge pressure from the GGR start countdown clock Robert set on our website, as well as from our current lack of sufficient funds. I interrupted my sponsor hunt almost 3 months ago due to this full time commitment working on Puffin’s hull. I had to use the idle summer load time in the boatyard (when I am the only customer in the paint shop), so I committed my efforts full time (12-13 hours daily 7 days/week) to hands-on work.

Consequently, I want to cut expenses where I can. I spend the night hours online, shopping for cheaper sandpaper, rubber gloves, overalls, etc. I‘d also like to minimize our expenses by planning ahead and making our schedule as efficient as possible… Accordingly, I intended to reinstall the rudder when we were done with the starboard side and Puffin returned to her vertical position to finish her paint job. The goal here was to save money by not having to call again for the travel lift for the separate rudder installation.

Well, the propeller shaft must be installed first, but this is the time to replace the cutlass bearing, right? In boating such replacements can take either a couple hours or many days, and I unfortunately got the latter of the two. Puffin was built in England in 1986 and the prop shaft is metric (30 mm), but the original replacement does not exist, of course. I have the choice to order a custom-made bearing or use undisclosed boatyard tricks :). Also, I had to learn a bit of the blacksmith’s trade while hammering the silicone bronze rod into carriage bolts holding the bronze rudder shoe in place. (The secret here is to heat up the rod with a torch until its end gets cherry-red.)

Regrettably, I missed my window of opportunity due to these detours, and the rudder/shaft installment got postponed when Puffin finally stood up on September 2. She had leaned on her port and starboard sides for almost one month, and we were excited to see her vertical again.

The Labor Day weekend is the last long summer weekend for most of the people in the U.S., but not for Janos and me. We took the “Labor” part seriously and dug ourselves into Puffin’s new projects…

To be continued in Part 5…